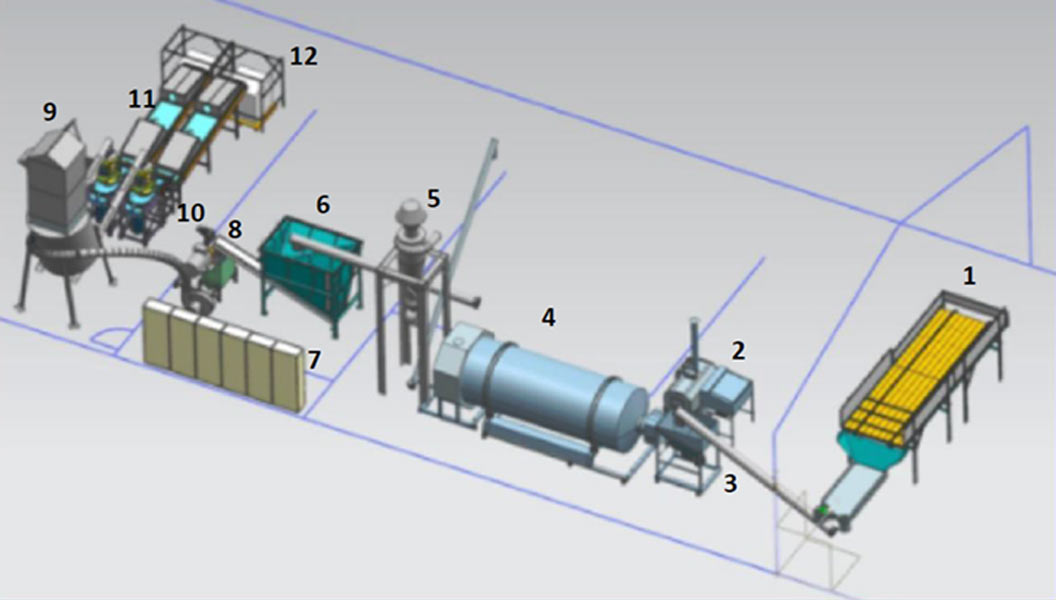

PRODUCTION LINES FOR PELLETS/BRIQUETTESPellets and briquettes are modern ecological fuel. Advantages are high calorific value and the possibility of heating the boiler automatically without manual reloading.

Contact CONTECHIN GROUP

Ask for indicative price quotation for a specific technology.

CONTECHIN GROUP s.r.o.

Adress: Úzká 162, 790 81 Česká Ves

ID: 25286846 Tax ID: CZ25286846