This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- How much beer do I want to produce in the microbrewery per month (year)?

- Who are the target customers? (only customers in my restaurant, established network of clients, a combination of both mentioned above)

- Do I plan to expand the microbrewery in the future?

- Do I plan to produce more types of beer in the microbrewery? (experimental area) or just few proven recepies?

Who is a microbrewery for?

Microbreweries are designed mainly for beer bars, clubs, restaurants and hotels that would like to differentiate themselves from the traditional way and would like to offer their customers something original. Pleasant atmosphere and unique taste of your own beer, which contains many vitamins, minerals and proteins is irresistible. Introducing a “living“ beer will attract more people to your business. Not only will the visitors remain loyal, but they will recommend you to their friends and colleagues as a place where they can spend their time and enjoy a glass of tasty “living“ beer, whether it is in their free time or during a business meeting. Purchasing a microbrewery can also be a purely business opportunity to build your own brands and distribution network. With our microbrewery CON-BEER® you find the right solution.

Why microbrewery?

The current trend of owning a private microbrewery is still booming. It allows the owners to offer unique, distinctive and “living“ beer to their customers. The “living“ beer retains many minerals and vitamins which are due to the pasterization destroyed in regular beer. Beer produced in microbrewery has a shorter shelf life (approximately 2 – 6 weeks according to the method of production and storage). The shelf time can be stretched by cold temperatures or filtration. Production of your own beer offers unique opportunity to stan dout from the competition. The competitive advantage can also be backed by the strong tradition, experience and high quality ingredients. Whether you want to produce and sell beer in a restaurant or you want to create a network of steady customers and offer them a production of their own brand, a microbrewery offers a wide range of options on how to start or expand your business and increase its attractiveness.

Why our microbrewery CON-BEER®?

- We deliver, assemble, start the production process, train your staff, provide the recipe, provide warranty and customer service, offer spare parts, provide raw materials.

- You participate on the design of your own microbrewery – we want to hear your opinion!

- The guarantee of purely Czech technology

- A high technical level and qality of processing – tanks are TÜV certified and accompanied by documents of origin of used materials.

- Modern and professional solution tailored to your needs

- Economically advantageous beer brewing concept

- Technologies tested by Czech brewers

- The guarantee of materials used for the technology (stainless steel does not corrode even after many years etc.)

- Optimal design of the brewhouse, heating and cooling leads to an economical operation and ensures stable conditions for brewing beer of the highest quality.

- A correct execution of the isolation of tanks

- Construction of the pressure vessel and welding quality (the effect of inflatable ball)

- Lower or upper fermentation? You do not have to decide before you buy your microbrewery. With our microbreweries it is possible to ferment both ways without additional equipment.

- We guarantee a long-term trouble-free brewing with achieving your performance goals

- Our tanks can be used for the whole technological cycle. They serve for fermentation, aging and at the end as over pressurized tanks without the need of transfering the beer to different tanks between stages. (saving space, time and money)

Microbrewery CON-BEER®

We deliver the CON-BEER® microbrewery according to you specific requirements and needs. The delivered technology meets all the necessary requirements of quality, reliability and an economically efective operation. The proposed solution of the CON-BEER® microbrewery is developed in cooperation with you, so it is a harmonious part of the current interior of your restaurant, bar or hotel. The customers will enjoy the unmistakable taste of your beer simultaneously with an attractive environment in which beer is brewed.

Microbrewery CON-BEER® 500 COMPACT

Double-wessel brewhouse of 500 l

Microbrewery CON-BEER® 500 COMPACT is the ideal candidate for the output expansion in the future – simply by adding CC tanks to a total number of 20 pieces and thus increase beer production by five times. If you are unsure about the future microbrewery expansion, never mind. Your microbrewery CON-BEER® 500 COMPACT requires no additional equipment to add CC tanks. All that is necessary to take into acount is greater capacity of space needed in this case.

Microbrewery CON-BEER® 500 COMPACT assembly is intended as a starting solution with an anticipated annual sales of 480 hectoliters (48 000 liters). The advantage of the assembly is its complete and optimal solution for the economic and effective run of the microbrewery.

Due the use of modern technology and CC tanks it is possible to brew up to 4 kinds of different types of beer with various fermentation in one production cycle (a month). Cylindrical-conical tanks are the ideal solution for bottom and top fermentation.. This eliminates one of the key decisions before microbrewery is designed – what type of fermentation will be used. There are several ongoing processes of beer production in CC tanks, including racking up the barrels! Microbrewery CON-BEER saves space and time and simplifies the operation. The entire brewing process and beer production can be fully automatic, semi-automatic or just manual. And again, all adapted to your needs and wishes

Microbrewery CON-BEER® 1000 COMPACT

Double-wessel brewhouse of 1000 l

Microbrewery CON-BEER 1000 COMPACT is the ideal candidate for the output expansion in the future – simply by adding CC tanks to a total number of 20 pieces and thus increase beer production by five times. Your microbrewery CON-BEER 1000 COMPACT requires no additional equipment to add CC tanks. All that is necessary to take into acount is greater capacity of space needed in this case

Microbrewery CON-BEER® 1000 COMPACT assembly is intended as a starting solution with an anticipated annual sales of 960 hectoliters (96 000 liters). The advantage of the assembly is its complete and optimal solution for the economic and effective run of the microbrewery

Due the use of modern technology and CC tanks it is possible to brew up to 4 kinds of different types of beer with various fermentation in one production cycle (a month). Cylindrical-conical tanks are the ideal solution for bottom and top fermentation.. This eliminates one of the key decisions before microbrewery is designed – what type of fermentation will be used. There are several ongoing processes of beer production in CC tanks, including racking up the barrels! Microbrewery CON-BEER® saves space and time and simplifies the operation. The entire brewing process and beer production can be fully automatic, semi-automatic or just manual. And again, all adapted to your needs and wishes.

Microbrewery is designed to fully comply with the latest needs and requirements. Professional solution, tanks with the TÜV certification and extended service life. Guaranteed use of high-alloy stainless steel resistant to sanitation solutions and aggressive cellars environment. Energy saving concept for more economical production of beer. Microbrewery allows the production of the healthiest “living“ unfiltered beer not only from Czech hops and malt, using Czech recipe, and trained staff by Czech brewer.

The design of your microbrewery will be created together with you, in order to match your needs and also in order to meet all the technical requirements for quality and reliability perfectly. In case you decide to add the microbrewery to your current business location (restaurants etc.), we will incorporate it into such an interior as its harmonic component. The microbrewery will support your business intentions, so that the customers can enjoy the “living“ beer with an unmistakable taste and at the same time enjoy the pleasant atmosphere and even watch the brewing process

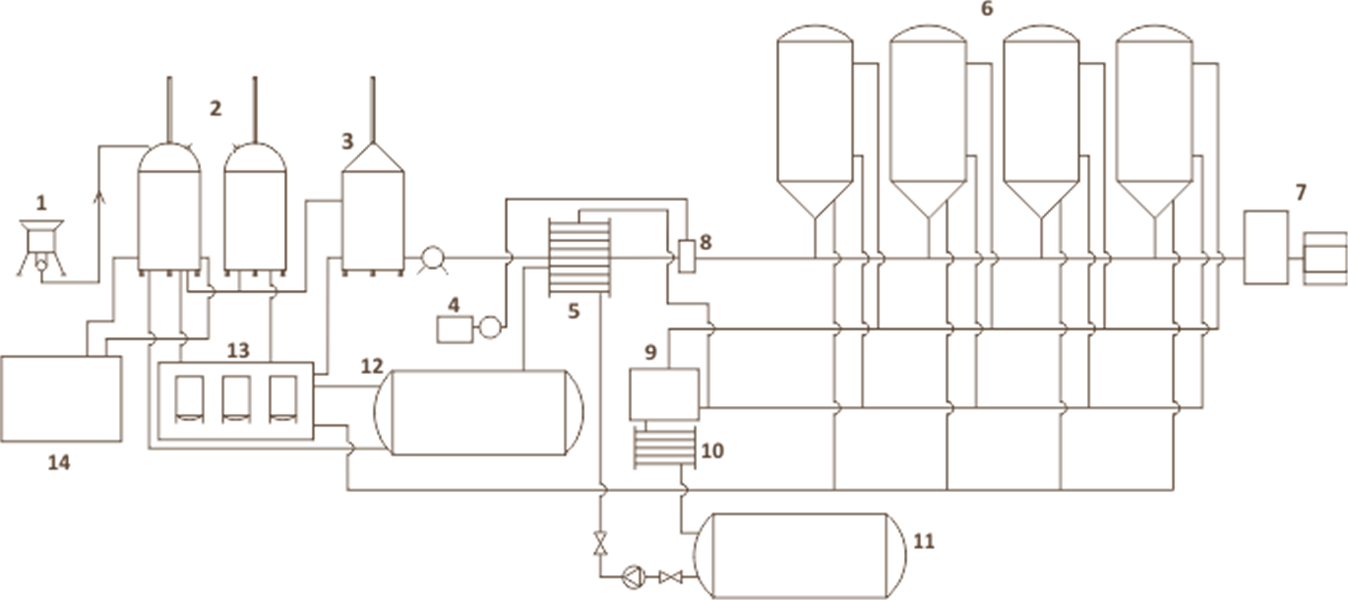

Hammer mill is used for crushing the malt. Crushing of the malt is a mechanical process, whose task is to crush the malt grains in order to make it possible for the fissel processes in the brewhouse to occur. Achieveing the optimal setting of the hammer mill should be based on the malt analysis, the mechanical composition of scrap, the wanted output and the draff analysis. The scrap is assessed by its overal volume, bulk density and sorting.

It is a 2-roller equipment designed to prepare grist for brewing with adjustable outcoming grain-size (adjustable gap between rollers from 0,3 to 1 mm). Matl feeding is done manually from 50kg bags. Same bags can be later re-used for the crushed malt. The maximum output is 100 kg of malt/hour which means that in two hours you have enough for one 1000 l batch.

As the name suggests, a whirling tank is used for a resuspension of the hot wort. During this proces, sludges are held in the middle of the tank and drained. Immediately after its settlement, the hot wort is cooled with the assistance of the plate wort cooler.

Plate cooler of wort is a heat exchanger in which the hot wort is cooled with ice water, made by using glycol refrigeration unit. Based on this principle, the wort is cooled down to + 6 ° C, which is the needed fermentation temperature. Before the fermentation, the wort is saturated with oxygen under sterile conditions, which is essential for the activity of the yeast. For separation of sludge and also aeration may be used the flotation of wort using air. The produced wort must with its concentration of the extract substances match the beer being produced.

The KEG barrel washer is semi-automatic. The whole process is very simple to operate. The staff only deploy and remove the barrels. The rest of the washing proces that is automatic includes: draining and depressurizing, first rinsing, washing using detergent solution, second rinsing and drying. The barrels can be sterilized and even pressurized with CO2 if needed. Washing process can be tailored and changed in order to meet the requirements before washing.

Filling is carried out through the filling valve into the kegs that were pressurized before.

The generator of ice water is a square double skinned insulated vessel made of stainless steel. A copper tube evaporator with distribution of a pneumatic mixing is placed inside and is flooded with water during the operation. From the above is the vessel equiped with a removable lid made of stainless steel. The device is provided with an overflow, ports for input and output of ice water, and a float valve for automatic refilling of water into the ice water maker cabinet. The vessel is mounted on adjustable legs.

By operating this unit, made ice water is used for cooling the wort to the fermentation temperature and afterwards down to the temperature needed for aging. This ice water also keeps the required temperature inside of the CC tanks. Our unit uses the glycol for the cooling process. The entire proces of cooling is accelerated and simplified. The quicker the boiling wort is cooled down to the fermentation temperature, the easier it is to preserve the properties, essential for a good beer taste and longer shelf life.

An isolated vertical pressureless vessel, in stainless steel, with temperature indication. Volume of the reservoir depends on the size of the brewery

A CIP station is designed for a sanitation of CC tanks, pipes and hoses. You can choose between

manual or automatic alternative. Part of the sanitary unit are also sanitation tanks that serve as a storage tanks for sanitizing solutions (acids and alkalis) and hot rinse water. Based on the customers requirements, tanks of various sizes and configurations are manufactured.

The tanks are standing cylindrical containers made of stainless steel, equipped with a hatch and technological necks, kept on legs with adjustable screws. They are fitted with a propeller stirrer for mixing the sanitation solution.

It consists of the lauter tun and the wort pan with a manual oparation, all in stainless steel with a cylindrical shell and steamers. The steam ventilation can be solved by a water condensator or into free space. Wort output is 5,5 hl. Brewhouse is steam-heated, and is equipped for both infusion and decoction mashing (2-3 mashings), mixing of milled malt and manual grist outcast. Our brewhouse allows mashing of malt beats and automatic ejection of draff with a manual final treatment.

The air compressor is oil free. It serves for aeration of the wort, pressurization of tanks and owerflowing of beer.

CC tanks are currently used in modern breweries. Compared to the traditional fermentation in open tanks. Beer production in CC tanks has several advantages:

– Excellent automatic sanitation

– Option of automatic fermentation process (reducing personnel costs)

– Reduced demand for the space needed

– A slight overpressure during fermentation accelerates the fermentation proces

– Closed CC tanks prevent contamination of the content by foreign organisms and do not require increased demands on sterility, as it is in the case of open fermentation vessels.

– CC tanks serve as fermentation wessels as well as lagering and overpressurized tanks

– In a cylindrical-conical tank it is possible to perform several consecutive operations. Requirements for space are smaller when using a CC tanks. Their shell is provided with so-called cooling zones by which heat is discharged during fermentation while cooling and lagering.

It aerates the wort before the main fermentation, using compressed, sterilized air.

In our microbrewery CON-BEER is the aeration plug mounted to a wort road pipeline and the air nozzle is connected to a supply of pressurized sterile air.

U deskového chladiče doporučujeme důkladnou sanitaci před každým použitím, aby se zabránilo zbytečnému zaklínění zbytků chmelového mláta nebo jiných přísad.

An isolated vertical pressureless vessel, in stainless steel, with temperature indication. Volume of the reservoir depends on the size of the brewery.

To create steam, either a gas or an electric steam generator can be used. It depends mainly on the possibilities of connections in areas designated for the specific microbrewery. Again, it is a device with a very simple operation system.

Practical recommendations for decision making when investing in microbrewery

When choosing a microbrewery it is crucial to choose the right size of the brewhouse. The sizes of fermenting and aging tanks (lagering tanks) are based on the size of the brewhouse. Modern microbreweries use CC tanks in which the whole process of brewing, including the racking of the beer, can run.

The projected monthly sales of beer are crucial for choosing the right size of the brewhouse and the initial size and number of tanks. Due to the fact that the production of beer of the Pilsen type takes about 4 weeks, are the monthly sales identical with the monthly production. The amount of batches per month is based on the monthly production.

When deciding the monthly sales we should consider the target group customers for whom we brew the beer. A restaurant where the average beer consumption is known is ideal for a microbrewery instalation. In order to increase the profitability, it is advantageous to make agreements with other

restaurants or businesses, offer your producion capacity and brew beer under their brand name for them.

The usual size of the CC tanks is twice the size of the brewhouse. Tanks of the same size as the brewhouse are only used for special types of beer that is only brewed less often in smaller quantities.

In our projections we have to calculate the starting monthly sales, but at the same time the microbrewery should allow a future expansion which can be achieved by simply increasing the number of tanks and therefore the number of batches per month. Therefore it is desirable to fulfill the initial monthly production when brewing for example two times a week. With this process we know that when using all working days it is possible to increase the production by 150% in the future.

When choosing a microbrewery and before signing the contract, make sure to examine what is and what is not included in the offer, what services are included at the time of the purchase as well as the time of the commissioning and subsequent operation. Sometimes, in an attempt to provide a lower price, the offer may be in the so-called minimalistic version, which can result in:

– Additional investments

– Uncomfortable operation

– Degradation of beer

– Shortening the service life

– Limitation of the long-term trouble-free operation of the microbrewery

The worst case scenario is to find out, after one or two years of operating the microbrewery and using the sanitation acid and lye solutions, that the stainless material is not of such a quality as it should be and does not last very long, especially in the welds. This often happens with very cheap imported technologies. In this situation, one can use a saying: „Some cheap things are just too expensive“. That is even more true, when talking about a long-term investment. This can be prevented for example by using stainless steel vessels which have a correct certification and documents of origin.

Contact CONTECHIN GROUP

Ask for indicative price quotation for a specific technology.

CONTECHIN GROUP s.r.o.

Adress: Úzká 162, 790 81 Česká Ves

ID: 25286846 Tax ID: CZ25286846